Industry Trends

Diamond Saw Blade Applied in Stone Mining

28/02/2020 / HITS:

In the past, China stone mining used to adopt explosions and flame cutting to extract granite rough block; the advantages of this were that the mining technology is easy to grasp, it is highly efficient, and the cost is low. But the method is likely to contribute to excessive rock fragmentation and dark burn, which can result in a low rate of quarry stone. What's worse, the blasting vibration will damage the internal stone and influence the intensity of the stone; in addition, safety conditions for explosion mining are poor, and the waste materials are harmful to the environment. Therefore, in recent years, with the improvement of mining facilities and technologies, the explosion and flame cutting method has been eliminated.

Currently, the most commonly used mining method is saw cutting mining, which includes wire saws, chain saws, circular saws, etc. Applied diamond wire saw stone mining has a history that goes back more than 3,000 years in some foreign countries. In earlier times, the wire saws were simply used in soft stone cutting. With the unremitting joint efforts of wire saw manufacturers and mining companies, the wire saw mining technology has grown, and the costs have been reduced substantially. Currently, wire saws are widely applied in the stone mining of granite, marble, sandstone, etc

The stone mining industry in China is an emerging industry. It has been a little more than a decade's time since the mechanization and environmental protection in stone mining technology were first introduced to China. Now China has developed the independent intellectual property right in circular saws equipment and circular saw blades. Combined with other mechanical mining equipment, China is now able to meet the basic demand for the current stone mining domestically.

Since circular saw stone mining machines and relevant saw blades are developed independently, China's technical level stands for the advanced international level. The newly-developed mining method has the highest efficiency, the lowest cost, and the biggest stone block production both in China and abroad. At present, the circular saws in stone mining have double saw blades and single saw blades, and the machine types include the expanded type and the narrowed type. The largest diameter of the installed saw blades can be 4.6m, and the vertical saw cutting depth can reach 2m, which is in accordance with the high requirements of processing stone blocks.

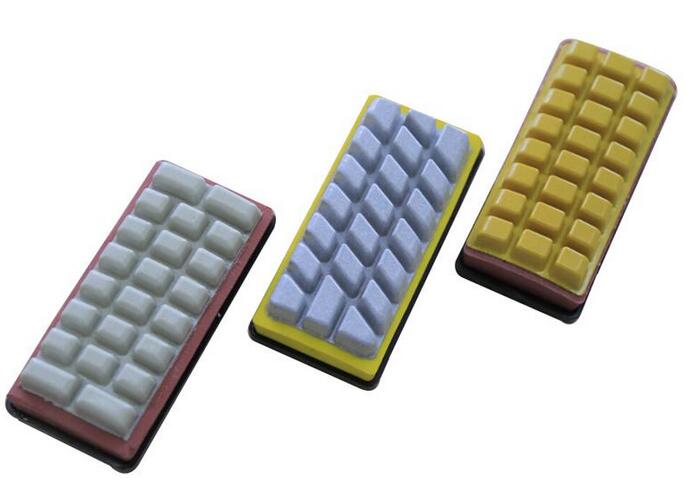

Diamond Fickert For Ceramic

Diamond Fickert was initially used for ceramic tiles polishing by Monte-Bianco in 2007 after ou...

Glaze Polishing Abrasive

Glaze polishing abrasives are used on normal polishing machines to make flexible full-polishing and ...

Diamond Wire Saw For Quarrying

Diamond wire saw for quarring is mainly used for quarrying granite and marble. Compared with the tra...

Diamond Wire Saw For Profiling

Diamond wire saw for profiling ...

Dry Squaring & Chamfering Wheel

Dry Squaring Wheel These dry squaring wheel products are suitable for make dry squaring on gla...

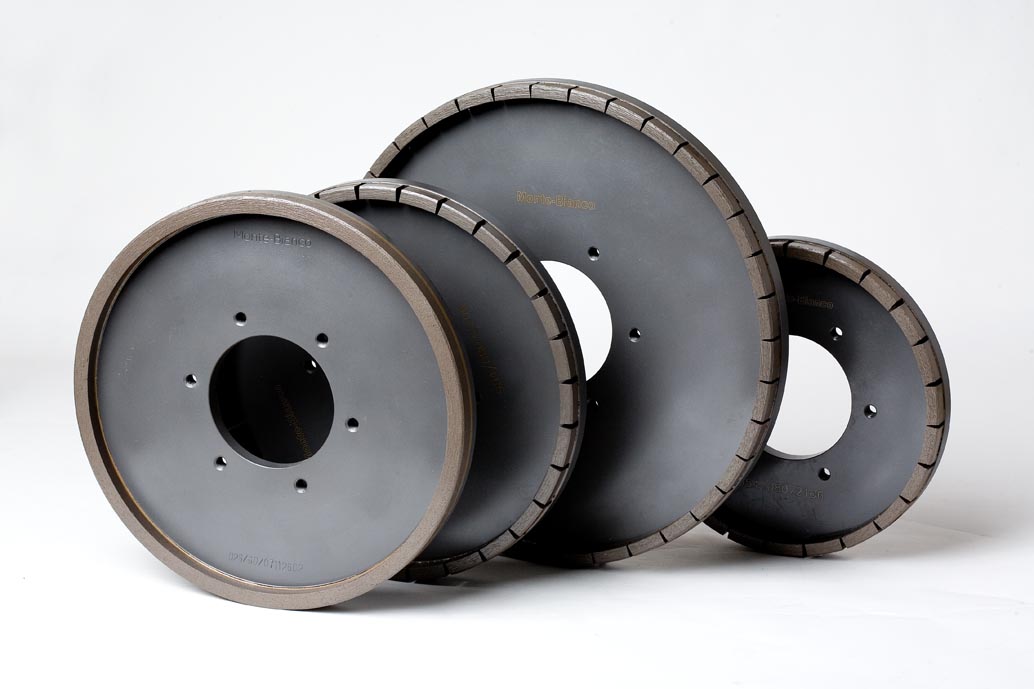

Metal Bond Diamond Squaring Wheel

Metal bond diamond disc squaring wheel is the most common used squaring tools for ceramic tiles edge...

Search News

Dimensional code scanner

Dimensional code scanner  Copyright © monte-bianco.com Guangdong ICP No. 05032889

Copyright © monte-bianco.com Guangdong ICP No. 05032889

Skype

Skype