Polishing Tools

HOME> PRODUCTS> Polishing Tools> -- For Ceramic

Search Product

Have a question?Ask us!

-- For Ceramic

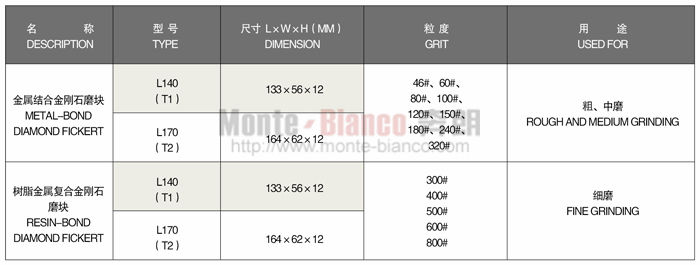

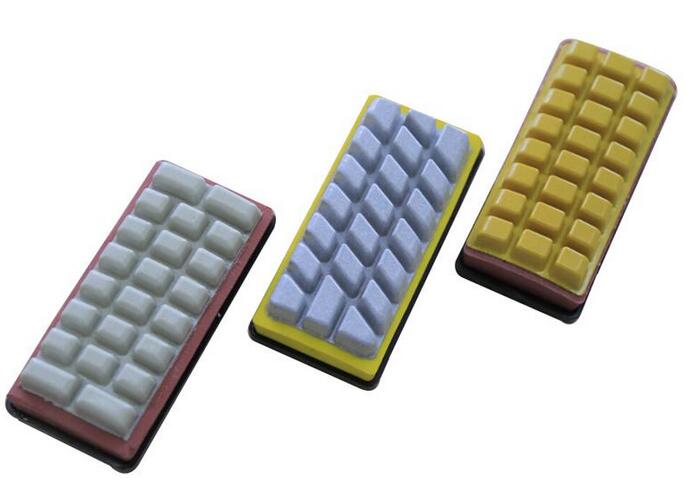

Diamond Fickert For Ceramic

Suitable machines:KEDA, ANCORA, BMR, PEDRINI, KEXINDA, LIBEN, KELID etc. various polishing lines

Application scopes:Various porcelain tiles, vitrified tiles, crystal tiles, floor tiles, wall tiles etc. in different sizes like 600x600, 800x800, 1000x1000, 600x1200, 300x300, 300x600 and so on.

- Overview

- Specifications

- Features

Diamond Fickert was initially used for ceramic tiles polishing by Monte-Bianco in 2007 after our several years of consistent and devoted research and development. This product has been highly approved by our customers according to their two years of practical use. Compared with traditional silicon carbide abrasives, this product’s advantages can be summarized as more efficient, energy saving and lower consumption. Diamond Fickert is the latest contribution made by Monte-Bianco to the technical upgrade and reform in ceramic tiles processing field. The development of this product is also one good example of Monte-Bianco following the Scientific-Development Sight of ‘Energy save, lower consumption and environment protection’ which is highly promoted by Chinese government now.

Metal Bond Diamond Fickert is used to make rough and medium grinding on ceramic tiles surface in the replace of traditional Silicon Carbide Abrasives. Our metal bond diamond fickerts are approved for their high grinding efficiency, excellent grinding effect, competitive price and performance ratio.

RELATED PRODUCTS

Copyright © monte-bianco.com Guangdong ICP No. 05032889

Copyright © monte-bianco.com Guangdong ICP No. 05032889

Dimensional code scanner

Dimensional code scanner

Skype

Skype