Working Conditions: Dry working

Suitable machines:KEDA, ANCORA, BMR, PEDRINI, KEXINDA, LIBEN, KELID, EDING etc. various chamfering machines

Application scopes: Glazed porcelain tiles, glazed ceramic tiles, wall tiles, floor tiles ect. in various sizes

Chamfering Tools

HOME> PRODUCTS> Chamfering Tools> -- For Ceramic

Search Product

QUESTIONS?

Need a quote?

Have a question?Ask us!

Have a question?Ask us!

-- For Ceramic

- Overview

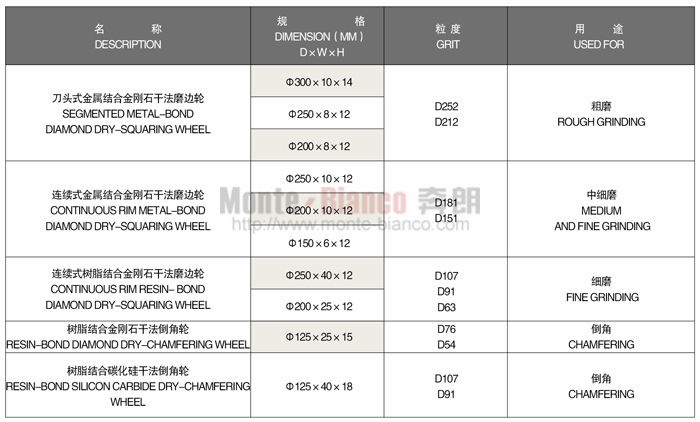

- Specifications

- Features

Dry Chamfering Wheel

The advantage of these produces is to make chamfering without water on ceramic tiles edges, which can achieve the same effect as traditional wet chamfering way. By the traditional wet mode, the tiles body will absorb water and some water will be still remained after drying, so ceramic tiles may become mildew and dyed when storing and transportation. But by dry chamfering mode, it can prevent effectively above mentioned quality problems, moreover the drying equipment and process become unnecessary, so the power consumption can be lowered, labor cost, drying equipment and related field can be saved.These products are suitable for make dry chamfering on glaze wall tiles. Our dry chamfering wheels are approved for their high grinding and cutting efficiency, excellent effect and stable performance.

The advantage of these produces is to make chamfering without water on ceramic tiles edges, which can achieve the same effect as traditional wet chamfering way. By the traditional wet mode, the tiles body will absorb water and some water will be still remained after drying, so ceramic tiles may become mildew and dyed when storing and transportation. But by dry chamfering mode, it can prevent effectively above mentioned quality problems, moreover the drying equipment and process become unnecessary, so the power consumption can be lowered, labor cost, drying equipment and related field can be saved.These products are suitable for make dry chamfering on glaze wall tiles. Our dry chamfering wheels are approved for their high grinding and cutting efficiency, excellent effect and stable performance.

RELATED PRODUCTS

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.

Dimensional code scanner

Dimensional code scanner  Copyright © monte-bianco.com Guangdong ICP No. 05032889

Copyright © monte-bianco.com Guangdong ICP No. 05032889

Skype

Skype